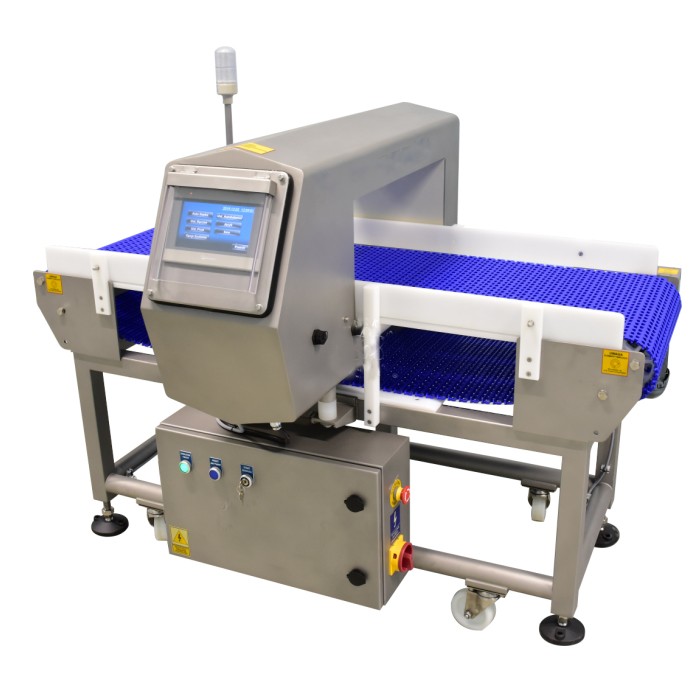

ELEKTRON-MD metal detector

for large products

ELEKTRON-MD metal detectors for large products are mainly used for testing products in the food industry. They are dedicated to the detection of meat, fish, sausages, seafood, vegetables and fruits, dairy products, nuts and dried fruits, ready-made products and bakery and confectionery products. The maximum dimensions of the tested product depend on the size of the probe detection window. The products under examination may be served loose or packed in plastic packaging, cartons or E1 and E2 boxes. The device detects contamination with foreign bodies in the form of ferromagnets and diamagnets.