FOOD STRIP CUTTING MACHINE QTJ500-II

Advantage

1. Precise cutting width.

2. Minimize labor cost, high efficiency.

3. Can work with strip cutting machine to produce same size strip product.

4. Can work with intelligent cutter to produce same weight product.

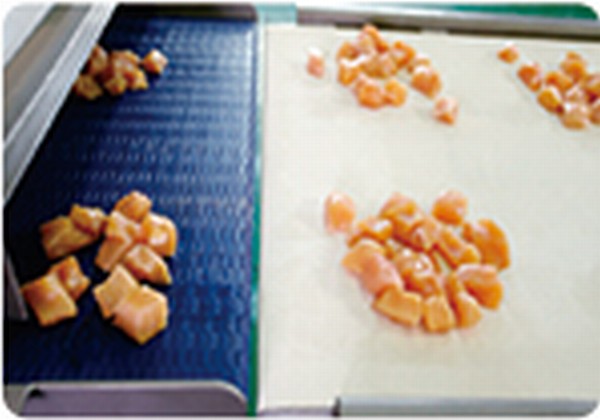

Meat stripping and dicing with circular blade. Suitable for fresh meat processing, including pork, beef and poultry.